Enhancing Safety: Key Considerations for Scaffolding with Plastic Sheets

Scaffolding is essential in construction for lifting materials to higher levels. However, it introduces inherent risks, including fall hazards and weather damage. Traditional scaffolding often lacks protective features, making it a potential source of injury. For instance, a fall from a scaffold could result in severe injuries, highlighting the need for safer alternatives. Additionally, weather conditions like rain or snow can degrade scaffolding, posing risks to both workers and equipment. These challenges underscore the importance of implementing safer scaffolding solutions, such as scaffolding plastic sheeting.

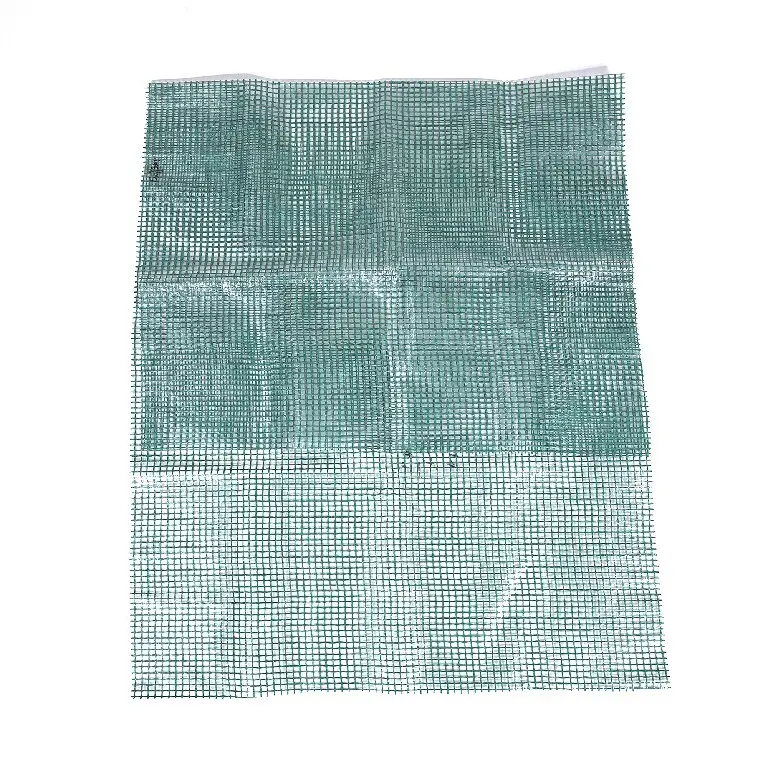

Benefits of Using Scaffolding Plastic Sheet

Scaffolding plastic sheeting offers numerous benefits that significantly enhance safety. One of its primary advantages is fall protection. Plastic sheets provide a barrier against falls, reducing the risk of accidents. This is particularly crucial in industries like construction, where falls are a common occurrence. Furthermore, scaffolding plastic sheeting is weather-resistant, protecting workers from rain, snow, and other adverse conditions. This durability ensures that scaffolding remains intact, maintaining its structural integrity and safety standards.

Another benefit is the ease of maintenance. Scaffolding plastic sheeting is simple to clean and repair, minimizing disruptions to construction activities. Regular maintenance prevents small issues from escalating into major problems, ensuring a safer working environment. The low maintenance requirements also make scaffolding plastic sheet a cost-effective solution, offering value for money in the long run.

Best Practices for Installing and Maintaining Scaffolding Plastic Sheets

Installing and maintaining scaffolding plastic sheet requires attention to detail to ensure maximum effectiveness. First, proper scaffolding must be secured to provide a stable base for the plastic sheets. This involves anchoring the scaffolding firmly to prevent movement or collapse. Next, the plastic sheets should be installed in a specific manner, ensuring they are flat and secure. Regular inspections are essential to check for any damage or gaps that might compromise safety. If any issues are identified, immediate action should be taken to repair or replace the affected areas.

Maintenance is equally important. Scaffolding plastic sheet should be cleaned regularly to remove debris and dirt, which could create hazards. Frequent inspections help identify any signs of wear or damage, allowing for timely repairs. Additionally, replacing scaffolding plastic sheet as needed ensures the scaffolding remains in optimal condition, maintaining its protective benefits.

Case Studies: Real-World Applications and Success Stories

Real-world examples demonstrate the effectiveness of scaffolding plastic sheeting. In a construction site in New York, replacing traditional scaffolding with scaffolding plastic sheet led to a significant reduction in fall incidents. Similarly, a manufacturing facility in Texas reported a decrease in equipment damage after implementing scaffolding plastic sheet, highlighting its durability and safety benefits. These case studies illustrate how scaffolding plastic sheet can improve safety and productivity, making it a valuable tool in various industries.

Comparative Analysis: Scaffolding Plastic Sheets vs. Traditional Safety Measures

Scaffolding plastic sheeting offers several advantages over traditional safety measures like guardrails and nets. While guardrails and nets provide basic protection, they lack the durability and weather resistance of scaffolding plastic sheeting. Traditional nets, for instance, can become tattered and ineffective in harsh weather conditions. Scaffolding plastic sheeting, on the other hand, is designed to withstand such conditions, offering a more reliable solution. Additionally, scaffolding plastic sheeting is easier to install and maintain, making it a more practical choice for construction professionals.

Current Trends and Future Prospects

The construction industry is continuously evolving, with new technologies emerging to enhance safety. Scaffolding plastic sheeting is one such innovation, with potential for further advancements in the future. For example, new materials and designs may offer even greater durability, flexibility, and safety. As technology progresses, scaffolding plastic sheeting is expected to play an even more significant role in making construction safer and more efficient.

The Imperative for Adopting Scaffolding Plastic Sheet

In conclusion, scaffolding plastic sheeting is a vital tool in enhancing construction safety. Its ability to provide fall protection, resist weather damage, and require minimal maintenance makes it a cost-effective and reliable solution. By adopting scaffolding plastic sheeting, construction professionals can significantly reduce risks and improve overall productivity. As the industry continues to evolve, scaffolding plastic sheeting is poised to become an even more essential component of safe construction practices. It is a clear and effective method to prioritize worker safety and ensure the successful completion of construction projects.

Transition Words and Phrases

On the other hand, traditional methods like guardrails and nets often fall short in terms of durability and effectiveness. Furthermore, scaffolding plastic sheeting offers a more practical and long-lasting solution. As an example, a recent study highlighted the superior performance of scaffolding plastic sheeting in preventing falls. Additionally, the integration of advanced materials and technologies in scaffolding plastic sheeting opens up new possibilities for future innovations. However, it is important to maintain a balance between cost and effectiveness when choosing the right scaffolding solution. Finally, the implementation of scaffolding plastic sheeting requires careful planning and execution to ensure its full potential is realized.

E-mail:sarah@winco-industries.com

WhatsApp:+86 15100181618

Add: 1602 NO.238 Huaian Road Shijiazhuang Hebei China.